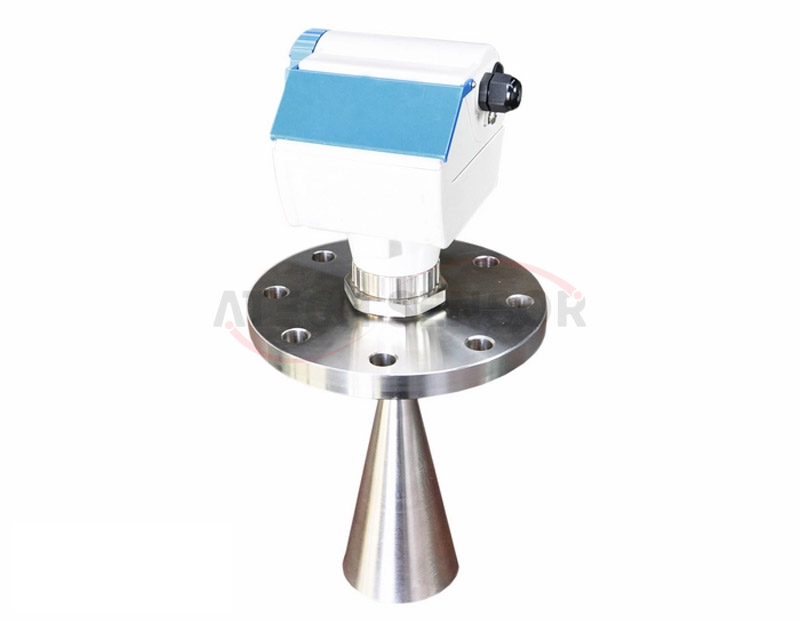

Radar level meter is a general-purpose radar level meter. It is a measuring instrument based on the time travel principle. Radar waves run at the speed of light, and the running time can be converted into a level signal through electronic components. The probe emits a high-frequency pulse that propagates at the speed of light in space. When the pulse encounters the surface of the material, it is reflected back and received by the receiver in the instrument, and the distance signal is converted into a level signal.

Product Description

Radar level meters transmit very short microwave pulses with very low energy and are transmitted and received by the antenna system. Radar waves run at the speed of light. The running time can be converted into a level signal by electronic components. A special time extension method can ensure stable and accurate measurement in a very short time.

Even if the working conditions are complex and there are false echoes, the latest microprocessing technology and debugging software can accurately analyze the echo of the object level.

Input

The antenna receives the reflected microwave pulse and transmits it to the electronic circuit. The microprocessor processes the signal and identifies the echo generated by the micropulse on the material surface. The correct echo signal recognition is completed by intelligent software with an accuracy of millimeters. The distance D from the material surface is proportional to the time travel T of the pulse:

D=C×T/2

Where C is the speed of light

Since the distance E of the empty tank is known, the level L is:

L=E-D

Output

By entering the empty tank height E (=zero point), the full tank height F (=full scale) and some application parameters, the application parameters will automatically adapt the instrument to the measurement environment. Corresponding to 4-20mA output.

Application medium

Intelligent radar level meter is suitable for non-contact continuous measurement of the level of liquid, slurry and granular materials, and is suitable for occasions with large temperature and pressure changes and the presence of inert gas and volatility.

It adopts the microwave pulse measurement method and can work normally within the industrial frequency band. The beam energy is low and can be installed in various metal and non-metal containers or pipes, without harming the human body and the environment.

Measurement method

It is a radar level meter based on the principle of time domain reflection (TDR). Part of the pulse of the radar level meter is reflected to form an echo and returns along the same path. However, considering the influence of corrosion and adhesion, the final value of the measurement range should be at least 100mm away from the tip of the antenna. For overflow protection, a radar level meter safety distance can be defined and attached to the blind area. The minimum measurement range is related to the antenna. Depending on the concentration, foam can absorb microwaves and reflect them, but it can be measured under certain conditions. Back to the pulse transmitter.

Measuring principle

The radar level meter is based on the principle of time domain reflection (TDR). The electromagnetic pulse of the radar level meter propagates along the steel cable or probe at the speed of light. When encountering the surface of the measured medium, part of the pulse of the radar level meter is reflected to form an echo and returns to the pulse transmitter along the same path. The distance between the transmitter and the surface of the measured medium is proportional to the propagation time of the pulse between them. The liquid level height is calculated.

Installation Instructions

(1) Wall to the outer wall of the short pipe: 1/6 of the tank diameter from the tank wall, the minimum distance is 200mm.

(2) It cannot be installed above the feed port.

(3) It cannot be installed in the center. If it is installed in the center, multiple false echoes will be generated, and interference echoes will cause signal loss.

(4) The pipe diameter should be less than or equal to the shielding pipe length (100mm or 250mm).

Things to note

1. The measurement range is calculated from the point where the beam touches the bottom of the tank, but in special cases, if the tank bottom is concave or conical, measurement cannot be performed when the level is lower than this point.

2. If the medium has a low dielectric constant, the tank bottom is visible when it is at a low level. At this time, to ensure measurement accuracy, it is recommended to set the zero point at a low height of C.

3. Theoretically, it is possible to measure the position reaching the tip of the antenna, but considering the influence of corrosion and adhesion, the final value of the measurement range should be at least 100mm away from the tip of the antenna.

4. For overflow protection, a safety distance can be defined and attached to the blind area.

5. The minimum measurement range is related to the antenna.

Advantages and Applications

1. Radar level gauge can measure liquid and solid media such as crude oil, slurry, raw coal, pulverized coal, volatile liquid, etc.;

2. It can measure all media with dielectric constant>1.2 in vacuum, and the measuring range can reach 70m;

3. Power supply and output signal are through a two-core cable (loop circuit), using 4...20mA output or digital signal output;

4. Non-contact measurement is easy to install, using extremely stable materials, strong and durable, accurate and reliable, with a resolution of up to 1mm;

5. Not affected by noise, steam, dust, vacuum and other working conditions;

6. Not affected by changes in medium density and temperature, the process pressure can reach 400bar, and the medium temperature can reach -200℃ to 800℃;

7. There are many installation methods to choose from: top installation, side installation, bypass pipe installation, waveguide installation;

8. There are many ways to choose from for debugging: programming module debugging (equivalent to an analytical processing instrument), SOFT software debugging, HART handheld programmer debugging, which is convenient and fast to debug

Selection points

Correct selection of radar level gauges can ensure better use of radar level gauges. The type of radar level gauge should be determined based on the physical and chemical properties of the fluid being measured, so that the diameter, flow range, lining material, electrode material and output current of the radar level gauge can adapt to the properties of the fluid being measured and the requirements of flow measurement.

1. Precision function inspection

Accuracy level and function Choose the instrument accuracy level according to the measurement requirements and the occasion of use to achieve economical and cost-effective. For example, for trade settlement, product handover and energy measurement, a higher accuracy level should be selected, such as 1.0, 0.5, or higher; for process control, different accuracy levels should be selected according to the control requirements; some occasions just detect the process flow, without precise control and measurement, you can choose a slightly lower accuracy level, such as 1.5, 2.5, or even 4.0, then you can choose a low-cost insertion radar level meter.

2. Measurable medium

Measurement of medium flow rate, instrument range and caliber When measuring general media, the full flow of the radar level meter can be selected within the range of 0.5-12m/s of the measured medium flow rate, which is a relatively wide range. The instrument specification (caliber) selected is not necessarily the same as that of the process pipeline. It should be determined based on whether the measured flow range is within the flow velocity range. That is, when the pipeline flow velocity is too low to meet the flow meter requirements or the measurement accuracy cannot be guaranteed at this flow velocity, it is necessary to reduce the instrument caliber to increase the flow velocity in the pipe and obtain satisfactory measurement results.

Maintenance of radar level gauge

The radar level gauge is mainly composed of electronic components and antennas, with no moving parts. It rarely malfunctions during use. The problem occasionally encountered during use is that some volatile organic matter in the storage tank will end up in the bell mouth of the radar level gauge. Or there are crystals on the antenna. They only need to be checked and cleaned regularly, and the maintenance is minimal.

In routine maintenance, you can use a PC to remotely observe the reflected wave curve. For new interference waves that may be generated later, you can use the liquid level meter to identify false waves to remove the influence of these interference reflected waves and ensure accurate measurement.