Melt pressure sensors are specialized devices designed to measure the pressure of high-temperature molten substances. In industries dealing with plastics, chemical fibers, rubber, and other polymers, these sensors play a pivotal role. They provide real-time data on the pressure within the melt, which is crucial for maintaining product quality, ensuring process efficiency, and safeguarding expensive production equipment.

1.How Do They Work?

At the heart of a melt pressure sensor lies a sensitive diaphragm. When the molten material exerts pressure, the diaphragm deflects. This physical change is then converted into an electrical signal. Typically, piezoresistive or piezoelectric elements are used. In piezoresistive sensors, the deformation of the diaphragm alters the resistance of the sensing element. This resistance change, following Ohm's Law, correlates to the applied pressure. For piezoelectric sensors, the mechanical stress on the crystal due to pressure generates an electric charge. The minute electrical signals are then amplified and conditioned by built-in electronic circuits. Finally, they are translated into standard output signals, such as 4-20 mA or 0-10V, which can be easily interfaced with control systems for further processing and analysis. This elegant transduction from mechanical pressure to electrical data empowers industries to have a precise handle on their melt processes.

2.Key Features and Advantages of Melt Pressure Sensors

Melt pressure sensors come with a suite of features that make them indispensable in modern manufacturing.

1: Autozero/Magnetic Zero, super anti-interference, one-click clearing, short-circuit clearing, and magnetic clearing, easy to debug on site.

2: Digital-analog integrated circuit design.

3: intrinsically safe, precise, stable, and reliable. Smart, safe, and User-friendly

4: Dynisco & Gefran Melt Pressure Transmitter Interchangable, Mercury-Free & AFT technology and alloy filling, non-toxic and eco-friendly, cost-effective and easy to use.

5: Multiple parameters can be customized: Kinds of high temperature, explosion proof, capillary-Exposed, Relay output, digital LCD display, Burst Plugs types for your choices, Imported stainless steel material, high accuracy level.

6: CE, RoHS, SIL2, PL"c" certified.

7: Rigid/Flexible Stem with/without thermocouple sensor structure optional, flexible conduit and special diaphragm isolation;

3.Installation and Maintenance Tips

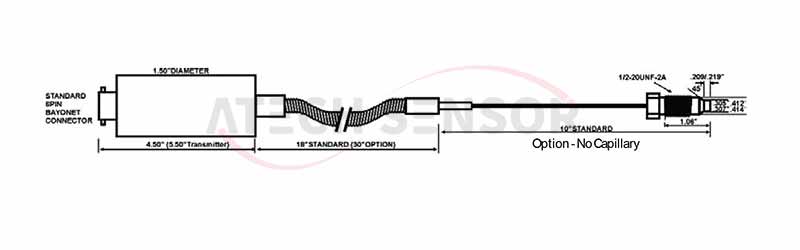

Proper installation is crucial for the reliable operation of melt pressure sensors. Firstly, during installation, the protective diaphragm cap should not be removed casually to prevent any accidental damage. The installation hole must be machined precisely according to the provided technical drawings. Any burrs or irregularities in the hole can scratch the diaphragm, compromising the sensor's performance.

Regular calibration is equally important. Over time, due to factors like temperature fluctuations and mechanical stress, the sensor's accuracy may drift. Calibration using professional equipment and following the manufacturer's guidelines should be carried out at recommended intervals. This process involves applying known pressure values and adjusting the sensor's output to match the actual pressure.

Maintenance also extends to routine cleaning. After use, especially in applications where the melt contains impurities, the sensor should be cleaned gently. Using a soft cloth and appropriate solvents (ensuring compatibility with the sensor materials), any residual melt adhered to the surface can be removed. Additionally, inspecting the cable connections and ensuring proper insulation safeguards against signal interference and electrical faults. By adhering to these installation and maintenance best practices, the lifespan and accuracy of melt pressure sensors can be significantly enhanced, providing consistent and reliable pressure measurements in industrial processes.

4.Applications in Different Industries

Plastics and Rubber Manufacturing

In the plastics and rubber industries, melt pressure sensors are ubiquitous. During extrusion processes, where polymers are forced through a die to create various profiles like pipes, sheets, or cables, the sensor monitors the pressure within the extruder barrel. This ensures the molten material flows uniformly, preventing issues such as die swell or uneven wall thickness. In injection molding, precise pressure control is essential for filling complex molds. By constantly measuring the melt pressure, manufacturers can optimize the injection speed and pressure profile, reducing defects like short shots, flash, or sink marks. This level of control not only improves the quality of end products but also boosts production efficiency by minimizing rework and scrap.

Chemical and Petrochemical

The chemical and petrochemical sectors handle a vast array of corrosive and high-temperature substances. Melt pressure sensors here are deployed in reactors, pipelines, and distillation columns. For instance, in polyethylene production, where high-pressure polymerization occurs, sensors track the pressure to maintain reaction stability. In petrochemical refining, they monitor the flow of viscous crude oil fractions, ensuring smooth operation through heat exchangers and distillation units. Any sudden pressure drop or spike can indicate a blockage, leak, or malfunction in the process. With real-time pressure data, operators can take immediate corrective action, preventing hazardous situations and costly shutdowns.

Textile and Fibre

In textile and fibre manufacturing, melt pressure sensors play a critical role in processes like fibre spinning. Synthetic fibres such as polyester and nylon are produced by melting polymer chips and extruding them through spinnerets. The sensor placed at the spinneret entrance measures the pressure, which dictates the fibre diameter and uniformity. Consistent pressure control results in fibres with even thickness, enhancing their strength and quality. This is especially crucial for high-performance textiles used in industries like aerospace, automotive, and sportswear, where fibre integrity directly impacts the final product's performance. By integrating melt pressure sensors, textile manufacturers can meet the stringent quality demands of modern applications.

5.Selecting the Right Melt Pressure Sensor

Choosing the appropriate melt pressure sensor is a decision that hinges on multiple factors. Firstly, the pressure range is critical. One must consider the maximum pressure that the system will encounter. As a rule of thumb, the sensor's pressure range maximum should be at least 1.5 times the peak anticipated pressure. This accounts for any sudden spikes or fluctuations that could otherwise damage a sensor with a narrower range. For example, in high-pressure polymerization reactors, where pressures can skyrocket, an adequately ranged sensor is non-negotiable.

Accuracy requirements vary by application. In some precision molding processes, like micro-injection molding for medical devices, a sensor with high accuracy (down to fractions of a percent) is essential to ensure product integrity. However, in less demanding applications, a slightly lower-accuracy sensor might suffice, balancing cost and performance.

Temperature range compatibility is another key aspect. If the process operates at extremely high temperatures, such as in advanced ceramics manufacturing where melts can reach over a thousand degrees Celsius, the sensor must be rated to withstand those thermal extremes. Some sensors come with built-in cooling mechanisms or specialized heat-resistant materials to function reliably in such harsh environments.

Chemical compatibility cannot be overlooked. In chemical plants dealing with corrosive acids or alkalis, the sensor's wetted parts need to resist chemical attack. Materials like tantalum or specialized ceramic coatings are used to protect the sensor and maintain its performance.

Finally, the output signal format matters. Common output signals include 4-20 mA, 0-10V, or digital protocols like HART or IO-LINK. The choice depends on the existing control system in the plant. For modern, digitally integrated factories, a sensor with a digital output can seamlessly interface with programmable logic controllers (PLCs) and other smart devices, enabling advanced data analytics and remote monitoring. Taking all these factors into account ensures that the selected melt pressure sensor will perform optimally in its intended application.