1.Sensor Introduction

In nature, when the temperature of an object is higher than absolute zero, due to the existence of internal thermal motion, it will continuously radiate electromagnetic waves to the surroundings, including infrared rays with a wavelength of 0.75 to 100 μm. Infrared temperature sensors are made based on this principle.

Temperature is a physical quantity that measures the degree of hotness or coldness of an object. It is a very common and important thermal parameter in industrial production. Many production processes require monitoring and control of temperature, especially in the production process of chemical, food and other industries. The measurement and control of temperature directly affects the quality and performance of the product.

2.Principle

infrared ray

Infrared is a type of light that is invisible to the human eye, but in fact, like any other light, it is also an objective substance. Any object, as long as its temperature is higher than the thermodynamic zero, will radiate infrared light to the surroundings. Infrared is the light outside the red light in visible light, so it is called infrared. Its wavelength range is roughly within the spectrum range of 0.75~100μm.

Infrared radiation

The physical essence of infrared radiation is thermal radiation. The higher the temperature of an object, the more infrared rays it radiates, and the stronger the energy of the infrared radiation. Studies have found that the thermal effect of various monochromatic lights in the solar spectrum gradually increases from purple light to red light, and the largest thermal effect occurs within the frequency range of infrared radiation. Therefore, infrared radiation is also called thermal radiation or heat rays.

Sensing principle

Thermal sensors use the radiation heat effect to increase the temperature of the detection device after receiving radiation energy, thereby changing the temperature-dependent properties of the sensor. By detecting the change in one of the properties, radiation can be detected. In most cases, radiation is detected through the Seebeck effect. When the device receives radiation, it causes a physical change in a non-electrical quantity, which can also be measured after being converted into an electrical quantity through appropriate changes.

3.Example

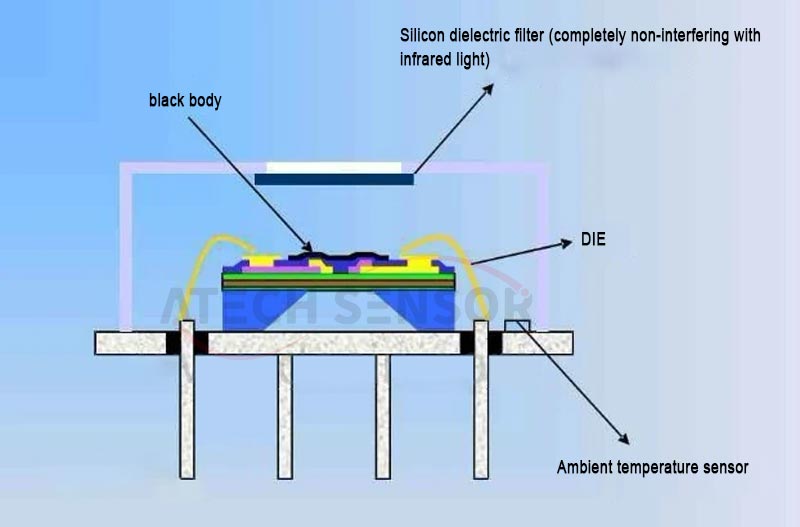

Infrared temperature sensor SMTIR9901/02/02sil

Product Introduction

The SMTIR99XX series is a silicon-based infrared sensor based on thermopiles. A large number of thermocouples are stacked on the bottom silicon substrate. The high-temperature junction and the low-temperature junction on the bottom substrate are isolated from their heat by an extremely thin film. The black absorption layer on the high-temperature junction converts the incident radiation into heat energy. From the thermoelectric effect, it can be seen that the output voltage is proportional to the radiation. Usually, the thermopiles use BiSb and NiCr as thermocouples. Because the infrared radiation characteristics are related to temperature, different filters can be used to measure different temperature ranges. Mature semiconductor processes are miniaturized and low-cost products. In order to meet certain applications, the infrared sensor opening angle can be designed to be as small as 7°.

Features

High precision

High sensitivity (110V/W) High signal-to-noise ratio (Rs~50kΩ)

Response time (40ms)

Low-cost thin film process

High-pass infrared filter (>5.5μm)

Standard TO05 package

Built-in Ni temperature sensor (02/02sil)

7.27 small viewing angle silicon lens (02sil)

4.Selection points

It is mainly considered from two aspects: performance indicators and environment and working conditions.

Performance indicators: The first is the range, that is, the temperature measurement range. When choosing an infrared temperature sensor, you must pay attention to its range. Only by choosing a suitable range can you measure better. The user's measured temperature range must be considered accurately and comprehensively, neither too narrow nor too wide. Secondly, you must pay attention to the size of the sensor. It cannot be too large or too small. You must choose a size that suits you to facilitate measurement. The range and size are what you should pay attention to when choosing a sensor. However, when choosing an infrared temperature sensor, you must also determine the optical resolution, wavelength range, response time, signal processing function, etc.

5.Temperature measurement module

SMTIRMOD09Sil/Std/Micro

Wide power supply options: 09Sil/Std: 4~16V; 09Micro: 2.2~2.3V

Low power consumption <2mA

Achieve 0.5% accuracy

I2C digital output

Viewing angle: 09sil: 14°; 09std: 70°; 09Micro: 120°

Measurable temperature range: 09Sil: <300℃; 09Std: 70°; 09Micro: 120°

SMTIRIN06

Rapid prototyping evaluation board

USB and RS232 interfaces for easy connection to PC

Free PC software

Infrared sensor input interface

6.Application

●Non-contact temperature measurement

●Infrared radiation detection

●Temperature measurement of moving objects

●Continuous temperature control

●Heat warning system

●Air temperature control

●Medical equipment

●Long-distance measurement