Products Description

Stainless steel pressure sensors use high-precision silicon sensors below 100 psi, protected by oil-filled stainless steel diaphragms. Devices of 100 psi and above use silicon strain gauges that are molecularly bonded to a stainless steel diaphragm.

We provide a complete range of services—from product inception, through design and prototypes, to manufacturing and testing. Our application engineers work closely with our customers to customize, design or create entirely new products. Call us—whether you’re an OEM, manufacturer, or end user.

Product Features

●1, 2 & 5 psi Low Pressure Ranges!

●All Stainless Steel Construction

●Gage, Absolute, Compound Gage or Vacuum Pressure

●Rugged Solid State Design

Product Specification

| Ranges | -15 to 50 psig, 0 to 1000 psia, 100 to 10,000 psig |

| Accuracy (Combined Linearity, Hysteresis and Repeatability) | ± 0.25% BSL, max |

| Minimum Resistance Between Transducer Body and Any Wire | 1M Ω @ 25 Vdc |

| Calibration | In vertical direction with fitting down, positive outputs only |

| Pressure Cycles | 10 million, minimum |

| Pressure Overload | -15 to 50 psig and 0 to 1000 psia: 3 times rated pressure or 20 psi, whichever is greater; 100 to 10,000 psig: 2 times rated pressure |

| Burst Pressure | -15 to 50 psig and 0 to 1000 psia: 4 times rated pressure or 25 psi, whichever is greater; 100 to 10,000 psig: 5 times rated pressure |

| Long Term Stability (1 Year) | ± 0.25% of FS, typical |

| Operating Temperature | -40 to 85°C (-40 to 185°F) |

| Pressure Port | ¼-18 MNPT |

| Pressure Port Material | -15 to 50 psig and 0 to 1000 psia: 316 SS; 100 to 10,000 psig: SS 316 or 17-4 |

| 0 to 500 psi: may contain HNBR o-ring in wetted pressure port assembly | |

| Bandwidth | DC to 1 kHz (typical) |

| CE | Compliant |

| Shock | 50 g, 11 ms half-sine |

| Vibration | ± 20 g |

| Response Time | <1 millisecond |

| Weight | PX309: 154 g (5.4 oz) |

| PX319/329/359: 100 g (3.5 oz) | |

| IP Rating | IP65 |

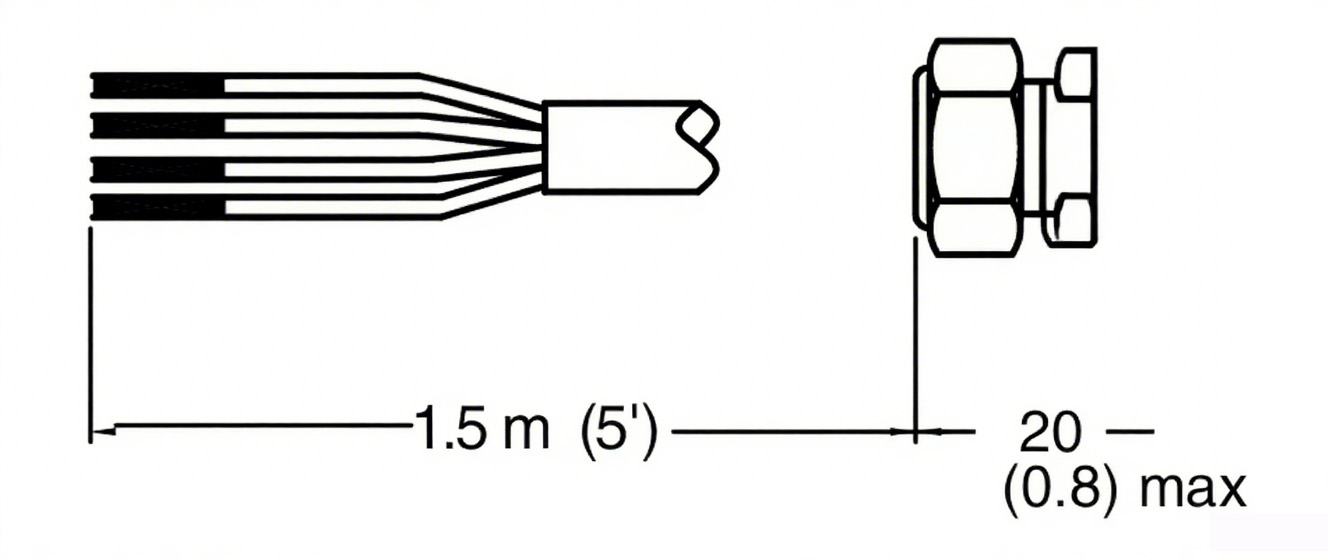

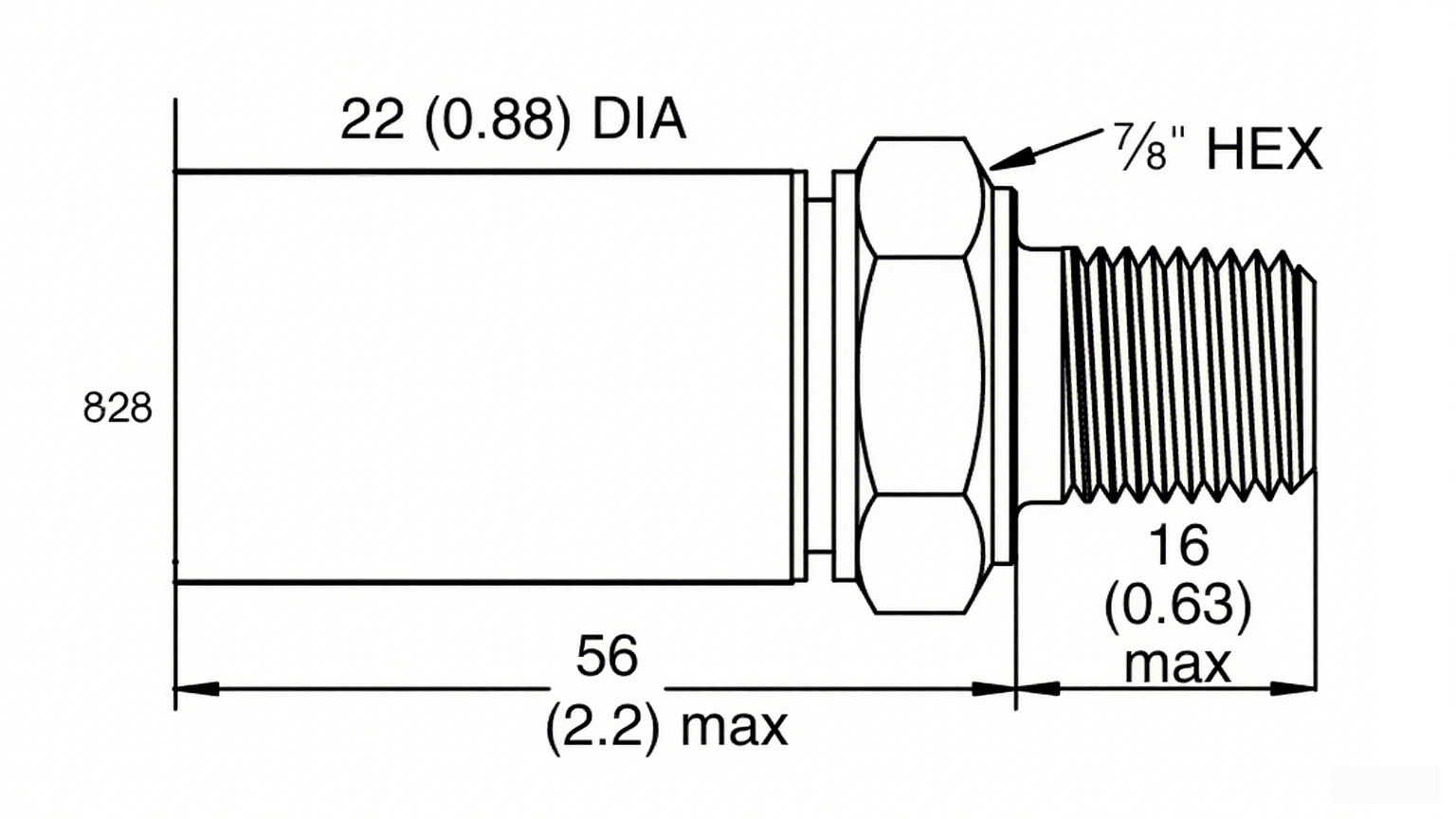

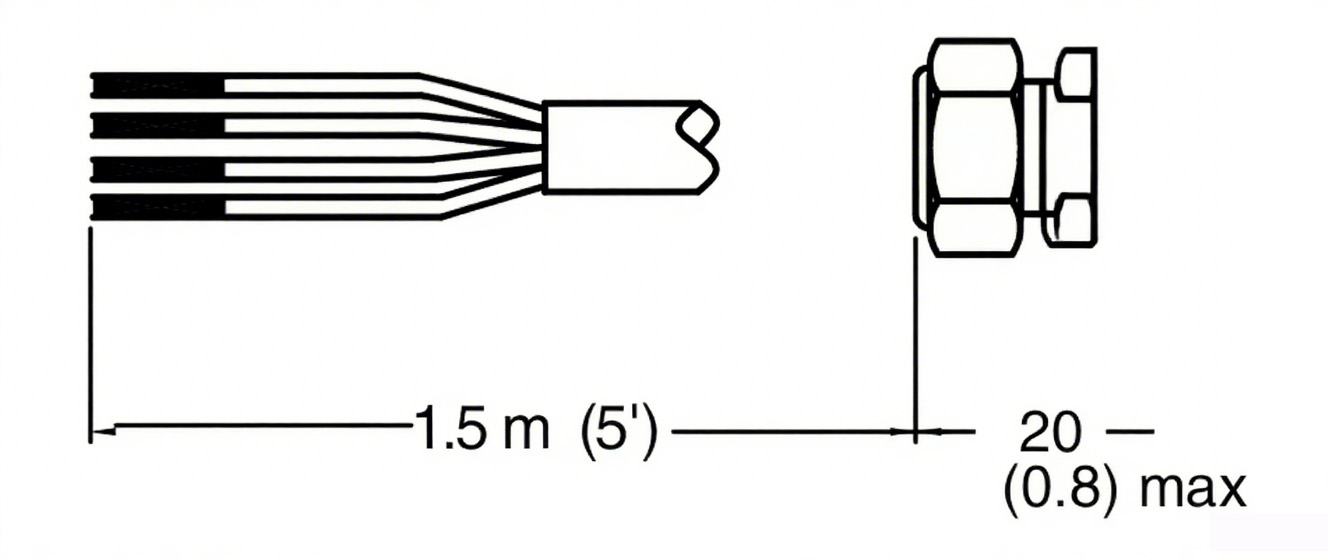

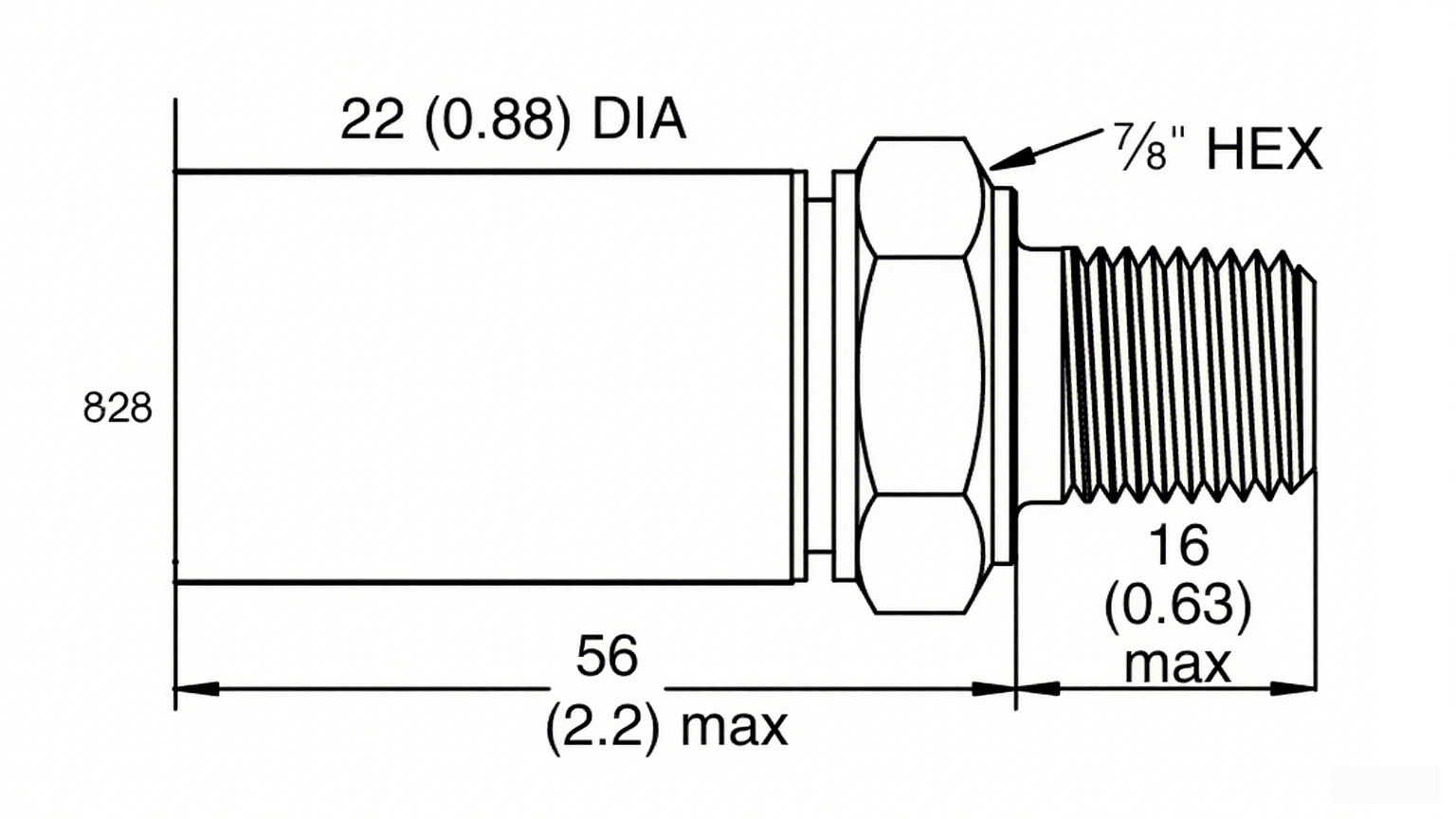

Product Dimensions

Product Features

●1, 2 & 5 psi Low Pressure Ranges!

●All Stainless Steel Construction

●Gage, Absolute, Compound Gage or Vacuum Pressure

●Rugged Solid State Design

Product Dimensions

Product Specification

| Ranges | -15 to 50 psig, 0 to 1000 psia, 100 to 10,000 psig |

| Accuracy (Combined Linearity, Hysteresis and Repeatability) | ± 0.25% BSL, max |

| Minimum Resistance Between Transducer Body and Any Wire | 1M Ω @ 25 Vdc |

| Calibration | In vertical direction with fitting down, positive outputs only |

| Pressure Cycles | 10 million, minimum |

| Pressure Overload | -15 to 50 psig and 0 to 1000 psia: 3 times rated pressure or 20 psi, whichever is greater; 100 to 10,000 psig: 2 times rated pressure |

| Burst Pressure | -15 to 50 psig and 0 to 1000 psia: 4 times rated pressure or 25 psi, whichever is greater; 100 to 10,000 psig: 5 times rated pressure |

| Long Term Stability (1 Year) | ± 0.25% of FS, typical |

| Operating Temperature | -40 to 85°C (-40 to 185°F) |

| Pressure Port | ¼-18 MNPT |

| Pressure Port Material | -15 to 50 psig and 0 to 1000 psia: 316 SS; 100 to 10,000 psig: SS 316 or 17-4 |

| 0 to 500 psi: may contain HNBR o-ring in wetted pressure port assembly | |

| Bandwidth | DC to 1 kHz (typical) |

| CE | Compliant |

| Shock | 50 g, 11 ms half-sine |

| Vibration | ± 20 g |

| Response Time | <1 millisecond |

| Weight | PX309: 154 g (5.4 oz) |

| PX319/329/359: 100 g (3.5 oz) | |

| IP Rating | IP65 |